Why the Aluminum Coil T-bend is so important for ACP panels bending ?

Why the Aluminum Coil T-bend is so important for ACP panels bending and the tips for the ACP grooving and bending ?

ALUSIGNPANEL ACP can be easily shaped into various shapes such as curve, curve corner, routing, grooving, punching, according to requirements of the building design which will make building looks more beautiful .

Almost all solid materials, including cured paints, have a measurable degree of ductility, which is the ability to sustain a change in shape. Aluminum, such as used on our painted Aluminum Composite Panels ( ACP ) , is highly ductile and can be bent at a relatively sharp angle.

The fluoropolymer-based paints we apply to our ACP panels are chosen for their exceptional durability and weather-resistance. If the bend is within the paint manufacturer’s specifications, it will retain the same integrity as it has on the flat surface of the panel.

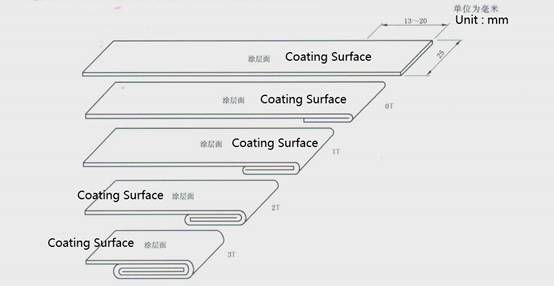

Paint manufacturers rate paint’s bending flexibility by the “T-bend test” (ASTM D4145 –see diagram below). Samples of painted metal are bent repeatedly back on themselves, similar to folding a napkin, and the painted edges are examined for film integrity. When the metal is bent upon itself three times – so that there are two inner layers of the Aluminum separating the outer layers produced by the final bend – the result is a “two-T” radius. The fluoropolymer-based paints we used are rated to withstand a two-T bend.

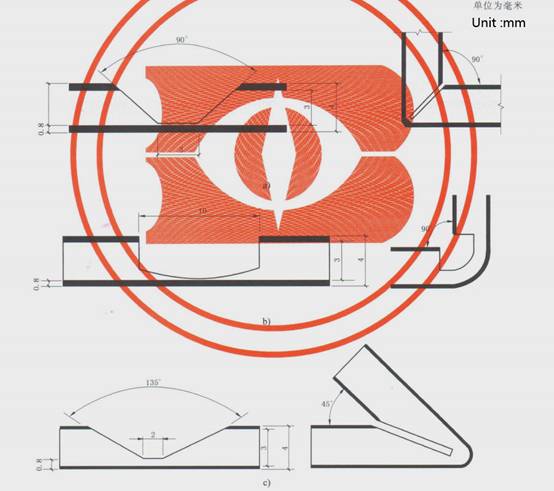

For fabricators, a reliable way to ensure that bends meet or exceed the two-T standard is to always maintain an outside radius of 2mm or greater. Any YBOND ACP panels bent at an outside radius tighter than 2mm is not covered under our warranty .

Simply place the inner, radiused part of the gauge directly against the bend in the ACP panel, with the flats of the gauge along the flat sides of the panel. For a 90° , 45° bend, the flat sides of the panel should fit snuggly into flats of the gauge. If this is not the case, and you can rock the gauge back and forth slightly without touching both panel sides at once, the radius of this bend is smaller than 2mm, which means cracking of the paint could eventually occur.

If the gauge fits perfectly, the bend radius is 2mm, and we warrant the paint against cracking. If there’s a gap at the bend while both flats of the gauge are flush against the panel sides, the radius is larger than 2mm – and of course our warranty applies for bend radiuses larger than 2mm as well.

Once you understand how the gauge works, it’s also easy to verify the bend radius for bends tighter than 90°. It’s simply a matter of observing how well the radius of the bend fits the radius of the gauge. For bends under 90°, we’ve provided 2mm cutouts on the outer edges of the gauge that can be used to evaluate the bend radius.

While it’s still important to pay close attention to routing depths and widths, we believe the new ALUSIGNPANEL radius gauge finally provides a definitive answer to whether the fabrication process is producing bends that meet the paint specification. That’s an answer every fabricator can use.

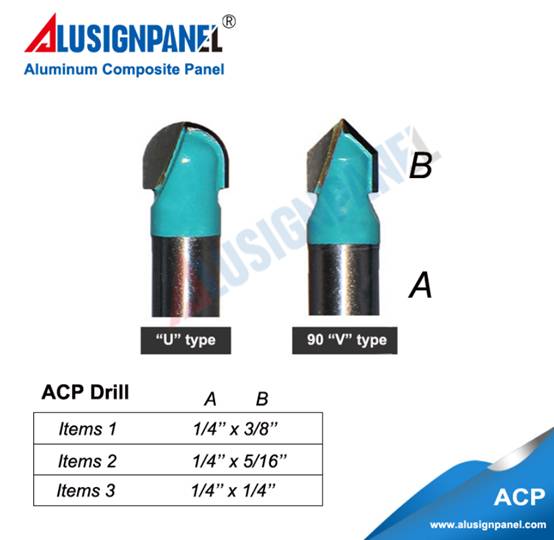

ALUSIGNPANEL also provide the grooving machine and the ACP grooving drills .