Aluminum Composite Panel Production Process

Aluminum composite panel is a kind of new decorative material consisting of two thin coil-coated aluminum sheets bonded to a plastic core, which is also known as Aluminum composite material in some area. Mostly it is called ACP or ACM for short.

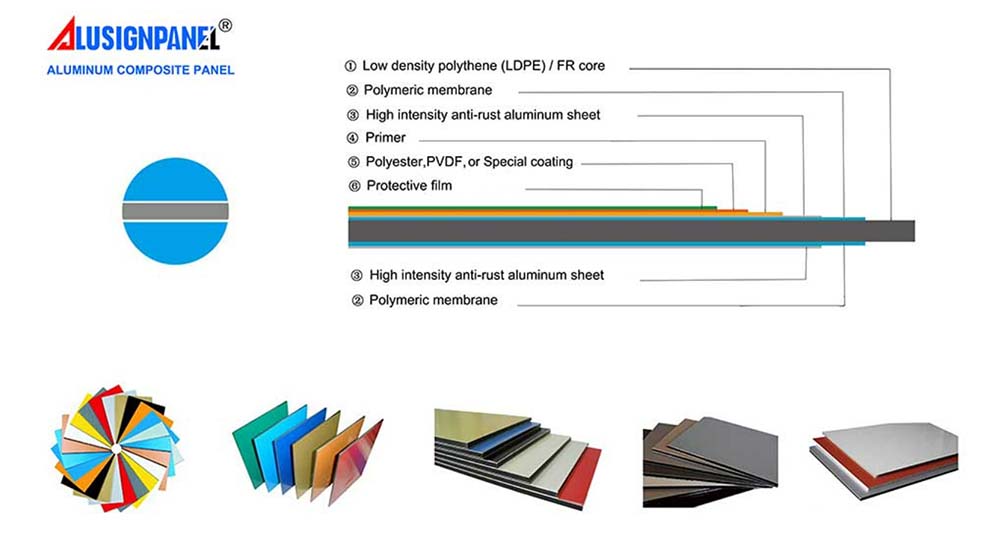

The main structure of Aluminum composite panel :

l Top Aluminum Sheet coated with Polyester or PVDF paint

l Polyethylene (PE plastic) or Fireproof Core

l Bottom Aluminum Sheet with Primer

The Aluminum composite panel is popular for its excellent performance like :

l Colorful design for decoration use

l Durable & Economic

l Light weight

l Easy on processing and installation

l Heat and sound insulation

l Easy maintenance

l Non-toxicity and Safety

l Super peeling strength

l Excellent coating property

Thus Aluminum composite panel is widely used in the building construction and advertising fields, such as: Curtain wall, building cladding facade, exterior and interior construction decoration, Auto 4S shop, shop front decoration, display fabrication, signage, digital UV printing, sign board and so on.

And here are the Aluminum Composite Panel popular size :

|

Width |

1220mm, 1250mm, 1500mm |

|

Length |

2440mm, 3050mm, 4050mm, 5000mm |

|

Panel Thickness |

2mm, 3mm, 4mm, 5mm, 6mm |

|

Alu.Skin Thickness |

0.10mm~0.50mm: 0.10mm, 0.15mm, 0.21mm, 0.30mm, 0.40mm, 0.50mm |

|

Standard Size |

1220mm x 2440mm (4' x 8'); 1500mm x 3050mm (5' x 10') |

|

Others |

Accept custom size too |

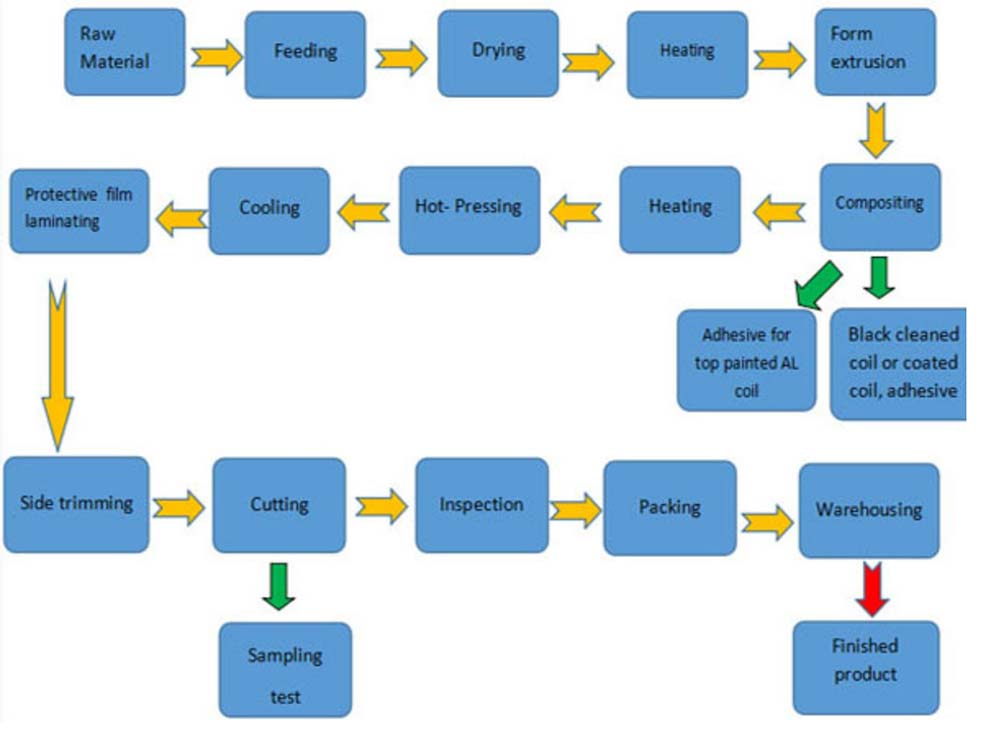

The main prouction process of Aluminum Composite Panels :

The first step : the raw Core Materials -Polyethylene Plastic ( or Fire rated Core ) particles extrusion forming into the different thickness core panels after the high temperature melting . At here we have the latest 14 heating sector before extrusion to sure the plastic 100% melt , and have the filters after the heating sectors , which can filter out the impurities that not be melted . After the extrusions , we have 5 rollers to compress the plastic into the different core thickness follows the production ACP orders instructions . The advantage of 5 rollers is the plastic core more smooth surface after lamination and the panels are harder than the old 3 rollers systems .

And Alusignpanel factory also update the Aluminum Composite filed latest Automatic feeding system .( as the pictures show )

The second step : the both side Aluminum Compositing with just extrusion form core panels together . The top side Color coated Aluminum coil + high polymeric membrane + Core Panel + Polymeric membrane + bottom primer paint Aluminum coil ( if both side colors ,just use the color coated aluminum coil instead , so both side any color panels are easy for us ). The high polymeric membrane are supplied by Liyuan group has coopearted Dupont for more than 15 years history , it is the first company to develop this materials . It leads the industry from glue connection materials to high polymer materials ; This is very important for the Aluminum Composite Panel peel strength .

The third step : the cooling systems after the thermal compounding process . We have update our cooling system longer to 18 meters and add 16 air cooler , to match the improving the high production speed , to insure the Aluminum Composite cold faster and the panels flatness .

The fourth step : protective film laminating and Online QC inspect . ( OEM film change at here )

The fifth step : aluminum composite panels width cut . The 1220mm width panels we use 1240mm width aluminum coil ( 1500mm width panels we use 1520mm width aluminum coil ) , both side cut off 10mm to insure the Aluminum composite panels are full paint , because the color coated aluminum coil hard 100% sure full paint , special on the aluminum border .

The six step : Aluminum Composite Panel levelling before length cut . ( so the panel custom length are easy for our Alusignpanel factory , recommend between 2.0 meter and 5.8 meters basic on the containers loading ) .

The last step : collecting the aluminum composite panel and packing . (Our factory also have update the Automatic machine doing this ) .

If request more information ,welcome to check our website : www.alusignpanel.com or contact us feel free via E-mail : [email protected] .