What’s the ACM (Aluminum Compsite Materials ) ?

1. What’sACM?

Aluminum composite material, abbreviated as ACM , It’s popular called in South & North Americas .( In the asia , the Mid East , it’s popular called ACP - Aluminum Composite Panel ; In the Africa , EU country popular called Alucobond directly ) . The ACM comprises a polyethylene core between two aluminum skin, the front surface is coated with Polyester (PE) or PVDF paints. Because of its colorful design and easy processing, it has been a popular material for the facade decoration and advertising use.

2. Where can we use theACM and What’s recommend thickness?

The ACM panels are mostly used in three aspects:Curtain wall Cladding ( exterior wall decoration ) andAdvertising,Interior wall decoration. Used in different aspects, the specifications ofACM building material also are different.

·

ACM panels for building curtain wall cladding (Exterior wall decoration ):

The minimum thickness of the upper and lower aluminumskin is 0.50mm, and the totalpanelthickness is not less than 4mm. The material of aluminum should meet the requirements of GB/T3880. Generally, aluminum alloy sheets of 3003, 5005 series should be used. The materials’ coating should be coated with fluorocarbon (PVDF Kynar ) , and request fire rated core materials .This type called : FR PVDF ACM Panels .

ACM panels for exteriorsignage board andAdvertising - printing .

Due to various superiority of the Aluminum composite material, such as light weight, easy on processing and colorful design, it has become one most applicable and popular material for the advertising use, like signage, digital UV printing, sign board, Auto 4S shop, shop front decoration, display fabrication and so on . The upper and lower aluminumskin are made of rust-proof aluminum with a thickness of not less than 0.20mm, and the total thickness should be3mm, 4mm. The coating is a polyester (PE )coating.

ACM Panels for indoor use:

The upper and lower aluminumskin generally adopt an aluminum plate with a thickness of 0.20 mm and a minimum thickness of not less than 0.15 mm, and the total panel thickness is generally 3 mm 4mm. The coating is polyester coated .

3. What’s the ACM size does ALUSIGNPANEL factory has ?

The following table show the ACM popular Specifications :

|

Width |

1220mm, 1250mm, 1500mm |

|

Length |

Any size, recommend 2440mm, 3050mm, 4050mm , 5000mm |

|

Panel Thickness |

2mm~ 6mm, recommend 3mm , 4mm |

|

Alu.Skin Thickness |

0.10mm~0.50mm, recommend 0.15mm,0.21mm,0.30mm , 0.50mm |

|

Standard Size |

1220mm x 2440mm (4' x 8'); 1500mm x 3050mm (5' x 10') |

|

Colors |

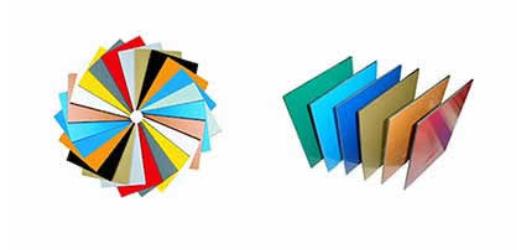

Factory’s standard 45 colors for reference |

|

Others |

Acceptcustom size and colorstoo |

Also could get more documents from our website download centre :https://www.acpfactory.com/down/list_1.html

4. Compare with other building materials, whyALUSIGNPANEL ACM panels are the most popular?

ALUSIGNPANEL ACM Panels VSAluminum veneer

(1)Aluminum veneer

Aluminum veneers have long been used in curtain wall decoration, but they are gradually declining.The reason is that the high unit price of the aluminum veneer is difficult to control the cost and is easy to cause waste ; Not easy processing and most of the designs need finishing on the factory , so not good for transport , will take high transport charges .

(2)ACM panels

The middle core layer of acm sheet is PE material, compounded by two layers of aluminum up and down, with various styles, strong plasticity, easy processing, and not easy to be deformed. It also has fireproof grade, and its cost is lower than that of aluminum veneers . It’s good building materials for the designers .

ALUSIGNPANEL ACM PanelsVS ceramic tile

(1)Ceramic tile

When speak of empty drum and falling of the tiles, most people have experienced. Apart from new homes, renovation of a house for a year or two, suddenly appeared empty walls, tiles off, not only will damage the furniture, bring reworking problems, but also pose a great threat to the personal safety of the family. And the decorative effect of the tiles is also monotonous.

(2)Acm panels

ALUSIGNPANEL fluorocarbonACM Panels is smooth , bright and colorful, with good decoration effect. At the same time, it has characteristics of strong plasticity, impact resistance, strong shock resistance.

Acmmaterial VS coating

(1)coating

Brush fire retardant coating is a good choice today, but most of the external wall paint has strong ordor, volatile toxic gases, while the external wall just dazzling for a short period after brushing, but it’s not waterproof and resistant to moisture, in a few years, the outer wall began to have large flake decoloring, causing mottled walls.

(2)Acm material

ALUSIGNPANEL art fluorocarbon aluminum compositematerials adopts FEVE fluorocarbon creatively for its surface, and its UV resistance and weather resistance are better than traditional curtain wall aluminum-plastic compositematerials to meet the requirements of high-grade weather resistance grades.

5.WhyALUSIGNPANEL ACM Panels are so popular?

(a)Small weight:

The acm material is made of aluminum and a relatively small density plastic core material. Therefore, compared with aluminum panel(or other metal) having the same rigidity or the same thickness, the quality is smaller than that of glass and stone.

(b) Good processability:

The aluminum-plastic composite panel is made of aluminum and plastic. It is easy to cut, punch, grooving, bending, etc. It can be processed by aluminum a material or wood processing equipment. Therefore, not only can it be processed in the production plant, the proposed composite board can be processed on site.

(c) Excellent fire performance:

The fire-resistant acm materials adopts the newly developed core material, which is filled with inorganic filler, so the fire performance has improved, and it can reach the B1 standard and meet the requirements of building regulations.

(d)High surface flatness:

The aluminum-plastic composite panel is produced by a continuous thermal composite production process, so that the surface flatness is higher than that of the single-material metal sheet, especially the large-sized sheet material is more obvious. It is used for building decoration and has a flat and uniform appearance.

(e) Good rigidity:

Compared with a single-layer aluminum plate, the aluminum-plastic composite panel has a large elastic limit and is not easily deformed, and can maintain good flatness performance for a long time in a natural state without too much external force.

(f) Rich in color and excellent decorative appearance

The layers of the aluminum-plastic panel can be made into a variety of colors, and the pattern design matching all uses can be carried out. In addition, the use of photocopying technology to simulate patterns of granite, wood grain and metal, to provide a unique texture, high-quality pattern design.

(g) Good durability:

The aluminum-plastic composite board adopts the metal and core material thermal composite technology, and the bonding is firm. The surface coating is made of different materials according to the use environment, and the fluorocarbon coating has more excellent weather resistance.

(h) Good cost characteristics:

The production of aluminum-plastic compositematerials adopts pre-coating continuous coating and metal/core material continuous thermal compounding process. Compared with general metal veneers, it has high production efficiency and low raw material cost, and is a material with good cost characteristics.

(i) Good environmental coordination:

The aluminum and plastic core materials in the discarded aluminum-plastic panel can be 100% recycled and have low environmental load. In addition, wood-aluminum compositematerials and outdoor decorative aluminum-plasticmaterials are made of fluorocarbon coatings, which have high durability and low daily maintenance costs, reducing the overall life cycle cost.

(j) Wide range of uses:

The acm material is cost-effective and has a wide range of uses. It can be used for the decoration of curtain walls, interior and exterior walls, foyers, restaurants, shops, conference rooms, etc. It can also be used for the reconstruction of old buildings, used as the counter, furniture, and vehicles. Inner and outer walls, etc.